New technology converts biomass into ‘coal’

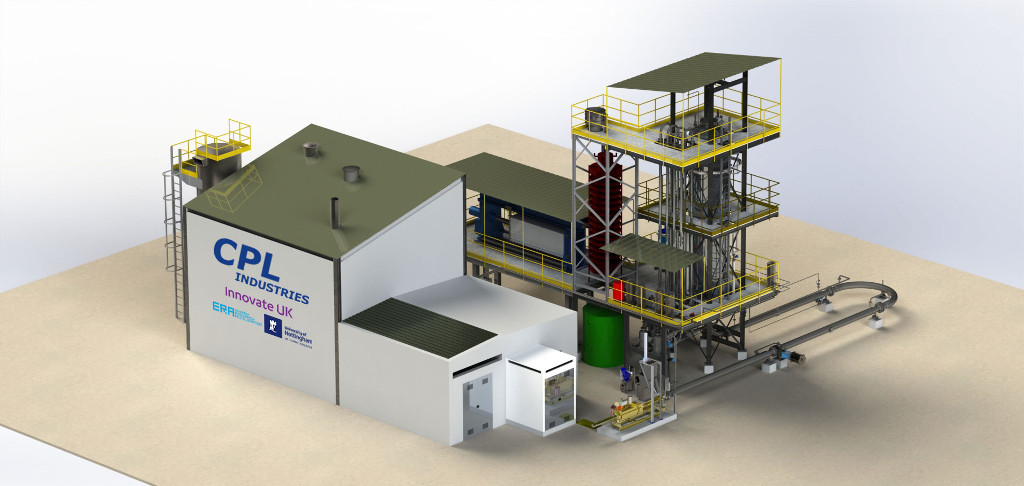

The University of Nottingham is partnering with the Energy Research Accelerator (ERA) and CPL Industries to produce a commercial scale facility capable of converting biomass into next-generation solid fuels with coal-like properties

The new facility is being supported by the Energy Research Accelerator (ERA) – an Innovate UK funded initiative involving the Midlands Innovation consortium of universities, together with the British Geological Survey and industrial partners, who are working together to support research and innovation in energy.

Mimicking coal formation

The technology being used to develop the biocoal is known as Hydrothermal Carbonisation (HTC). This converts high-moisture biomass into solid fuels using moderate temperatures and high pressures. The HTC process effectively mimics the long-term natural process of coal formation, with the process taking a matter of hours rather than millennia!

Once completed, the HTC facility will be operated by CPL Industries, a manufacturer and distributor of solid fuels which already has products on the market containing biomass materials.

CPL is working with Professor Colin Snape at the University of Nottingham, who is Director of the Centre in Efficient Power from Fossil Energy and Carbon Capture Technologies.

First facility in the UK

Speaking about the HTC facility, Professor Snape said: “Developing this new HTC facility is very exciting as this is the first such plant in the UK. We will be able to look at how we can convert waste streams into value-added fuel products that have many domestic and industrial applications. Also, by using the biocoal that has been made from biowaste, we are producing a carbon-neutral fuel and reducing greenhouse gas emissions.”

The installation will be located at CPL’s production site in Immingham, North Lincolnshire, and is scheduled to begin production in mid-2018.

Demonstrating cutting-edge innovation

Gordon Waddington, Chief Executive of the Energy Research Accelerator (ERA), which is funding the development, added: “This facility is a great example of what ERA is aiming to do – demonstrating cutting-edge innovation, with industrial partners who can advise on the commercial application of the products.

“By tapping into the experience of CPL and the expertise of Professor Colin Snape and his team at the University of Nottingham, I am confident that we will be able to demonstrate that producing biocoal using this technique, has significant commercial potential.”

Commercial and environmental benefits

Speaking about the new facility Jason Sutton, Director of CPL, said: “The technology has the potential to revolutionise the treatment of high-moisture organic waste streams, producing value-added products that displace fossil fuels and promoting the circular economy. CPL and the rest of the project partners stand ready to engage with local authorities and waste managers to source suitable waste material, conduct trials and develop the wider commercial and environmental benefits.”

The intention for the HTC facility is to investigate suitable replacements for fossil fuels in its home heating products, with possible future developments being the replacement of coking coals in industrial applications such as foundries and smelters.

Demonstrator projects

The HTC facility in Immingham is one of a number of demonstrator projects and facilities that the Energy Research Accelerator is investing in across the Midlands, in order to increase innovation in energy generation, storage, distribution and use.

Email: enquiries@era.ac.uk